NAstra

Description

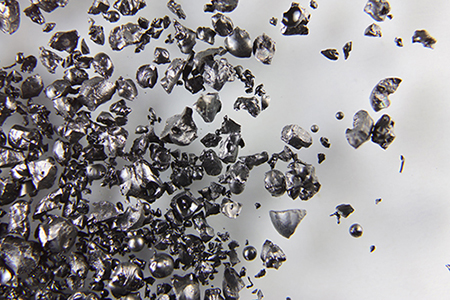

NAstra is produced in accordance with DIN EN ISO 11126-3. It is a perfect blasting grit for blast cleaning steel, stone and concrete, and for the removal of mill scale, rust, old paint and dirt.

During melting of ore concentrates an iron silicate is formed. This is passing a groove and is granulated at a temperature of approximately 1250 °C, using a temperature-controlled pressurized water jet. After cooling down in a tank with fresh water, the fine particles are separated from the granulate manufactured in this way. It is a vitreous amorphous slag, it does not absorb water. During the manufacturing of the abrasive no crushing or grinding procedures are included. Therefore, the single abrasive particle is not broken up and retains its extreme hardness and tenacity which is the case for all particle sizes.

NAstra is used as blast cleaning abrasive for all application fields in conventional corrosion protection on almost all surfaces. It is suitable for surface preparation standards SA-3, SA-2½, SA-2 and SA-1. It is a non-hazardous material, containing less than 0,1% free crystalline silica.

Grain sizes

| NA10 | 0.2 - 1.0 mm | NA25 | 0.2 - 2.5 mm |

| NA14 | 0.2 - 1.4 mm | NA28 | 0.2 - 2.8 mm |

| NA514 | 0.5 - 1.4 mm | NAST | 0.5 - 2.5 mm |

| NA20 | 0.2 - 2.0 mm | NA428 | 1.4 - 2.8 mm |

Packing

- 3-ply paper bags of 25 kg, on shrinkfoiled export pallets.

- Strong woven polypropylene big bags, with 4 lifting loops.

- Other packing options on request.

Product categories

Industry solutions

Downloads

Contact

Would you like to find out more about the products we sell and their applications? Request further information or a quotation. We look forward to hearing from you.

EP Power Grit GmbH

Duisburger Straße 170

46535 Dinslaken